Sealing Solutions for Electrical Enclosures

In today's technologically advanced world, electronics power our everyday lives. From smart devices to industrial machinery, these electronic marvels have become an integral part of our existence.

But in order to shield these sensitive components effectively they require secure protection against dust, moisture, and electromagnetic interference (EMI) – which is where our sealing solutions come to the rescue.

While upon initial inspection, seals may appear inconspicuous, their role is in fact paramount in preventing substances from inadvertently traversing between environments. Sealing profiles serve as a crucial safeguard, protecting the contents of its enclosure from the elements.

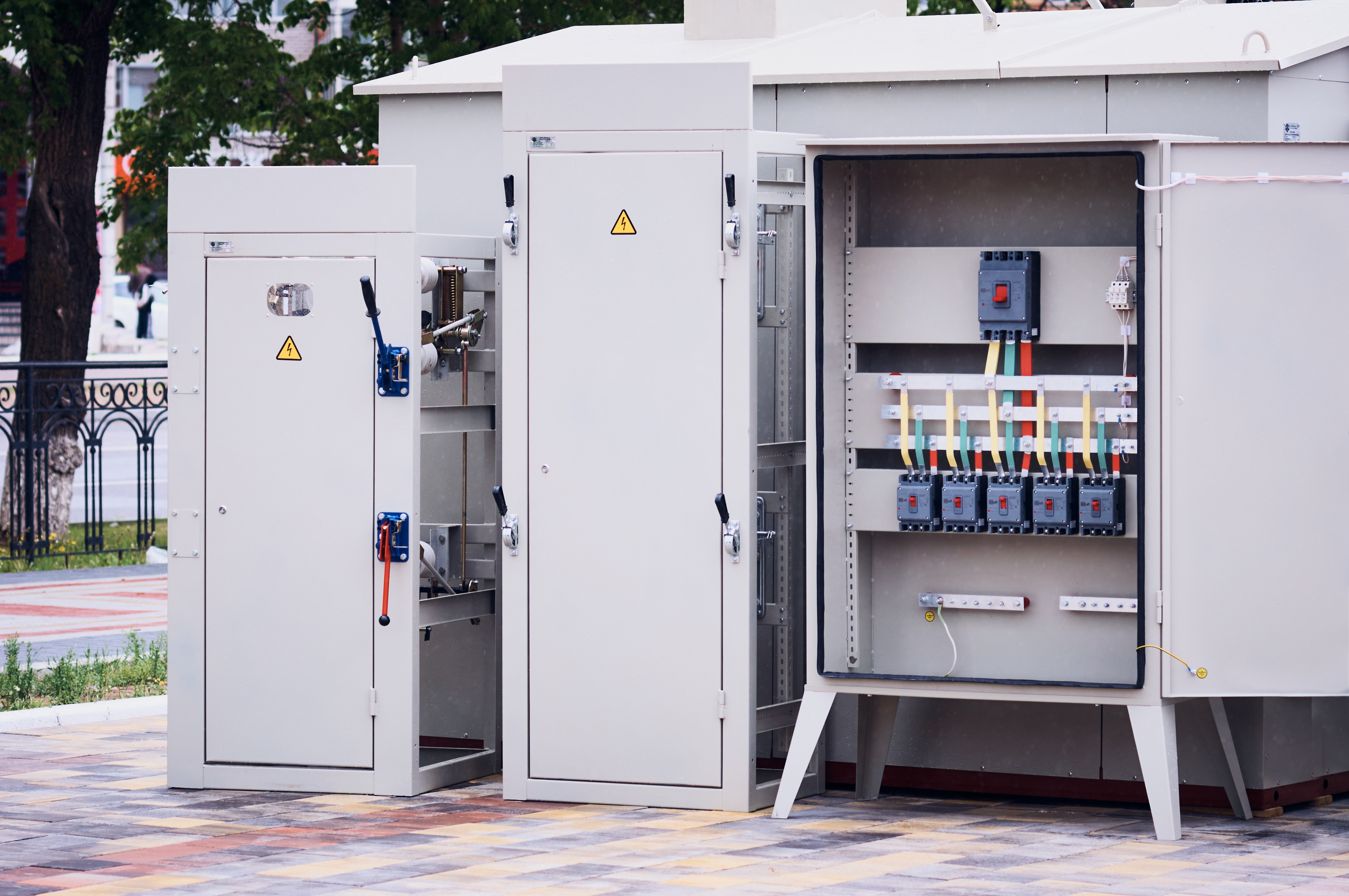

The Role of Electrical Enclosures

Electrical enclosures play an essential role in thousands of applications throughout different workplaces across a vast range of industries and sectors. They act to contain or enclose electrical equipment and devices such as switches, relays, PCBs (printed circuit boards), integrated circuits, power boards, processors, electrical power supply lines, and much more.

By housing such items, these enclosures provide an effective means of protecting these vital components and can extend the working life of these devices making them an invaluable hardware investment.

Electrical enclosures can take many different forms and are determined by their use, purpose, and/or location. Possible applications can include enclosure boxes for telecommunications units, traffic light controls, railway junctions, communication masts, and power generators to name a few.

Another example would be electric vehicle charging stations which rely on components such as gasket seals (typically made from materials like silicone, rubber, or neoprene and is commonly used to create a compressible barrier that forms an airtight and watertight seal), environmental seals (to seal out rain, not degrade under UV and high temperatures, and not crack in freezing temperatures), flame retardant gaskets (commonly used in sealing applications when flame retardant and anti-static characteristics are critical to your application), and EMI shielding gaskets (typically made from conductive materials, create a barrier that protects sensitive electronic components from external interference) among others.

These applications can be housed in a wide range of sizes meaning that no matter what its purpose serves, there is sure to be an electrical enclosure that will be ideal for the job and a range of suitable seals ready to keep them protected.

The Importance of Choosing The Right Sealing Solution

There are many factors to consider when choosing the best components to seal an electrical enclosure. When selecting materials for electrical enclosure seals, several critical factors come into play. First and foremost is environmental compatibility.

The seal material must be able to withstand the specific conditions the enclosure will face, whether it's exposure to moisture, extreme temperatures, or corrosive substances. Additionally, the material's resilience to wear and tear is crucial, as it ensures the seal remains effective over time. Compatibility with the enclosure material is also pivotal; the seal should bond well and create a reliable barrier.

Furthermore, considerations such as compliance with industry standards and regulations, cost-effectiveness, and ease of installation play significant roles in material selection. Ultimately, a thorough assessment of these factors ensures that the chosen seal material provides robust and reliable protection for the enclosed electronic components.

Here at FA Parkes, our fully qualified engineers are on hand to help you navigate our extensive product range to ensure you find the right part for your application.

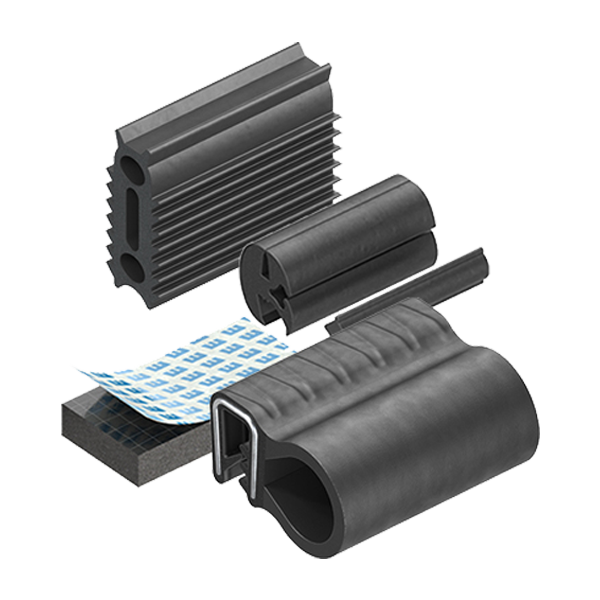

Our product selection includes a wide variety of components and a comprehensive selection of sealing products includes seals which offer edge protection, in addition to O ring seals, gaskets, and gasketing seals, and flat profile seals.

Choosing The Right Materials

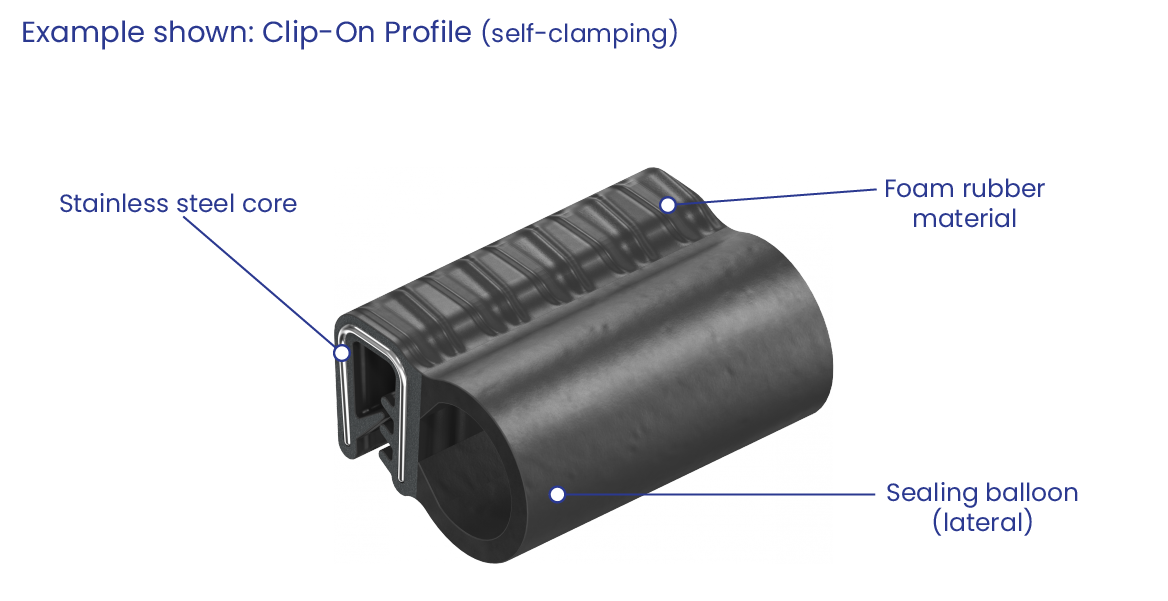

A popular choice often used in the production of seals is to use a stainless steel core due to its corrosion resistance, durability, and overall robustness.

Different types of stainless steel offer varying levels of corrosion resistance. In Europe, the European standard EN 10088 for classifying stainless steel is the standard classification system, although the AISI (American Iron and Steel Institute) classification system which is specific to the United States is more commonly used internationally.

The AISI system categorises steels based on their chemical composition and properties, while EN 10088 provides a standardised classification framework for stainless steels in Europe and offers more detailed information about the steel's composition.

In the AISI system, it categorises stainless steels into series, such as 200, 300, and 400 series. The 300 series, particularly types like 304 and 316, are widely used in electrical enclosures due to their excellent corrosion resistance properties.

For example, in the AISI system “304” is a widely known grade known for its excellent corrosion resistance and versatility. However, it doesn't provide detailed information about the steel's composition.

Meanwhile, in the European standard, instead of just a number, it uses an alphanumeric code. For example, "X5CrNi18-10" breaks down into different components:

- "X" indicates it's a high alloy steel.

- "5" signifies the percentage of chromium.

- "CrNi" indicates the presence of both chromium and nickel.

- "18-10" specifies the precise percentages of chromium (18%) and nickel (10%) in the steel composition.

Selecting the appropriate stainless steel standard ensures that the enclosure's seal can withstand the precise environmental conditions it will face to safeguard the electronic equipment.

With regards to the seal casing, silicone-based gaskets are a prevalent choice due to their remarkable flexibility and resistance to moisture, dust, and temperature fluctuations. Neoprene, recognised for its robust sealing properties, also boasts excellent resistance to oils and chemicals, making it invaluable in industrial settings. EPDM (ethylene propylene diene monomer) stands out for its durability and exceptional UV resistance, rendering it an excellent option for outdoor applications where exposure to the elements is a concern.

Additionally, PVC (polyvinyl chloride) and TPE (thermoplastic elastomer) seals offer cost-effective solutions without compromising on sealing efficiency, presenting suitable choices for various enclosure projects. For more demanding environments, fluoroelastomers like Viton come into play, providing outstanding chemical resistance, and finding their niche in settings with harsh industrial chemicals. Each material caters to specific conditions, ensuring reliable protection for sensitive electronic components across diverse applications.

Waterproofing for Sealing Solutions

When selecting sealing solutions, understanding IP (Ingress Protection) ratings is also crucial. These ratings indicate the enclosure's ability to protect against dust and water intrusion. The higher the IP rating, the better the protection. Consider the environmental conditions your electronics will face, such as outdoor exposure, high humidity, or submersion, and choose a sealing solution that matches those requirements.

IP ratings indicate the degree of protection an enclosure offers against the intrusion of solid particles and liquids. The format of an IP rating is typically "IPXY," where "X" represents protection against solids (ranging from 0 to 6) and "Y" denotes protection against liquids (ranging from 0 to 9).

For example, an enclosure with an IP67 rating is dust-tight (level 6) and can withstand immersion in water up to 1 metre for a limited time (level 7). This information is vital because it allows engineers and designers to match the sealing solution to the specific environmental conditions the enclosure will face.

A higher IP rating implies a more robust sealing solution. For instance, in environments with heavy exposure to dust or moisture, it is imperative to choose a sealing solution with a higher IP rating to ensure the longevity and functionality of the enclosed electronics.

From The Names You Can Trust

All of our sealing products for electrical enclosures are sourced from leading brands, such as Albert Jagger, DIRAK, EMKA, PINET, and Industrilas. This ensures that when you order from FA Parkes, you can do so with the total confidence that comes from knowing that you will receive a sealing product of the highest quality available.

With over 50 years of experience as a leading name in supplying the enclosure industry, we pride ourselves on being recognised experts, offering the products our customers trust to produce highly effective sealing solutions for their electrical enclosures.